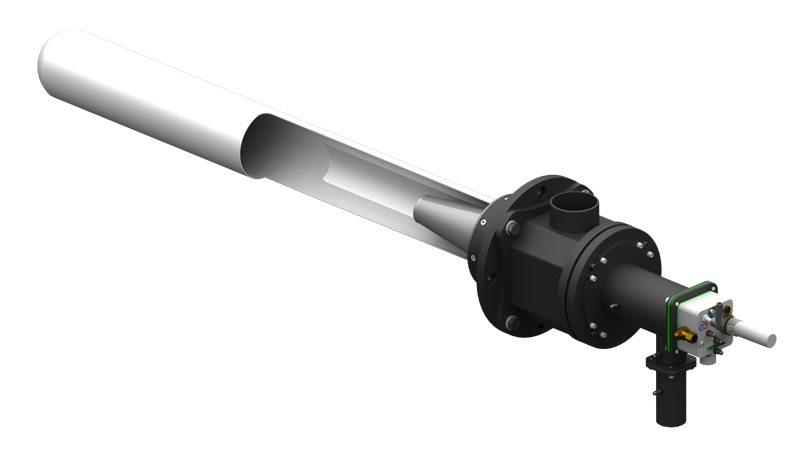

ECO FUSE-R-SC0150

New Process Burners

ECO FUSE-R-SC0150

AREA OF APPLICATIONS

- Forging Processes

- Reheat processes

- Ladle heating processes

- Casting vessel heating processes

- Scrap preheating operations

- Stress relief processes

- Aluminum melting processes

- Thermal fluid heaters

- Thermal oxidizers

- Refractory drying units

- Glass tank heating systems

- Fiber blanket processing in all other heat treatments and processes that require high temperature and flame stability industrial furnaces, such as tunnel or car furnaces, stretching furnaces, ceramic furnaces, fiber insulated furnaces used in processes.

Features:

- Capacities in the range of 12-6000 kW

- Indirect and direct system

- Gas-fired combustion

- With ambient air or preheated air ability to work

- Excess air capacity

- Desired square for fiber and concrete walls and circular section refractory head options

- Direct ignition

- Photocell as flame detector and ionization options

- Elegant and functional design

- Economical fuel consumption

- Short cycle times

- Homogeneous heat distribution in the oven

- Excellent flame stabilization

- High proportionality

- As a single stage at high capacities option to work

- Low NOx and CO emission values