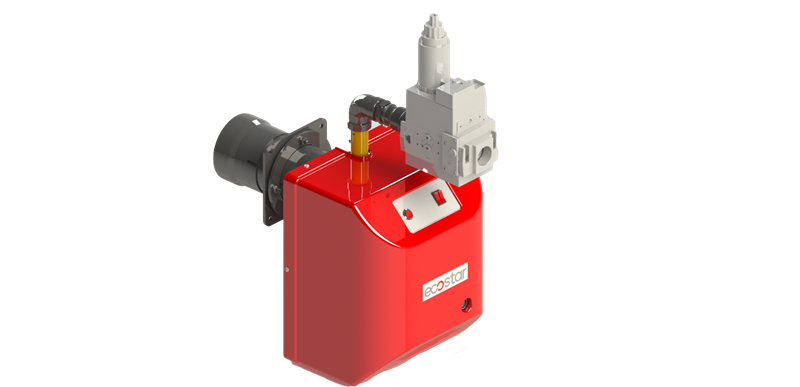

Monoblock Burners

Two-Stage Square Gas Burners

ECO 2.0 G C 2

- Two-stage operation,

- Optimum fuel / air mixture with special gas nozzle,

- Compact design and operation at low noise levels,

- Ionization flame control,

- Sliding flange for connection to different boiler types,

- Automatic control equipment of the burner according to European standard EN-298,

- Easy access to all equipment without dismounting the burner from the boiler,

- Adequate gas supply control with minimum gas pressurestat.

- Combustion air control with air pressurestat,

- Easy installation and operation,

| Burner Type | Capacity | Capacity | Natural Gas Consumption | LPG Gas Consumption | Fan Motor Power | Voltage at 50 Hz | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Min. kcal/h | Max. kcal/h | Min. kW | Max. kW | Min. Nm³/h | Max. Nm³/h | Min. Nm³/h | Max. Nm³/h | kW | VAC | |

| ECO 2.0 G C 2 | 43.000 | 129.000 | 50 | 150 | 5,21 | 15,64 | 1,91 | 5,73 | 0,11 | 1N 240 |

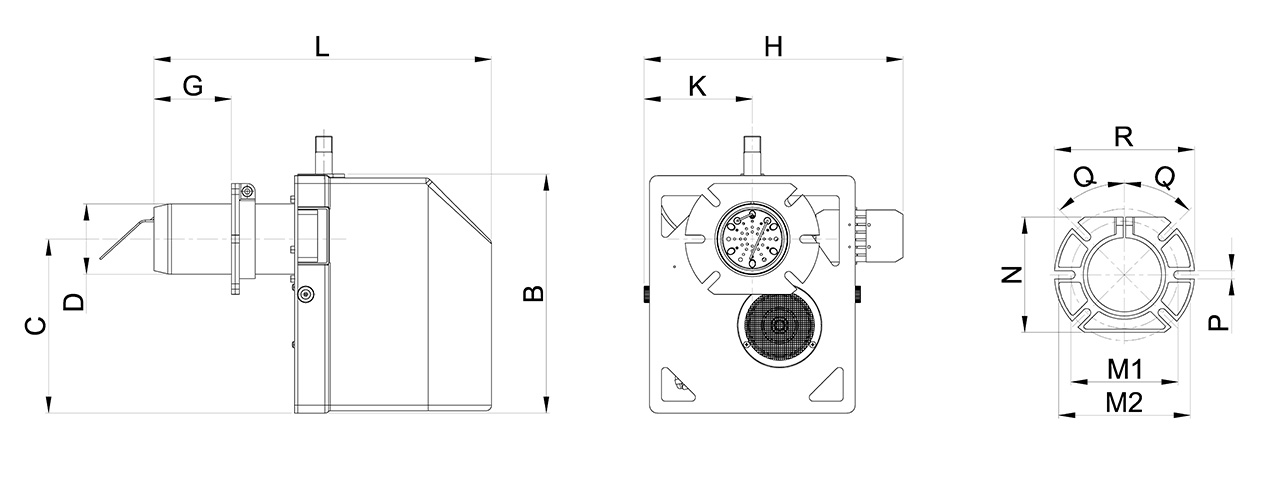

| * | L | Gmin | Gmax | H | K | B | C | D | M1 | M2 | N | R | P | Q |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ECO 2.0 G C 2 | 625 | 80 | 250 | 396 | 172 | 455 | 295 | 134 | 195 | 220 | 185 | 230 | 10 | 45 |

*All dimensions in mm.

| SPECIFICATIONS | ECO 2.0 G C 2 |

|---|---|

| Control Type | 2K |

| Air flow adjustment | SM |

| Adjustable flame tube extension | |

| Gas Valve | |

| Minimum gas pressure switch | |

| Maximum gas pressure switch | |

| Air pressure switch | |

| Flame control | İO |

| Ignition | DA |

| VPS Gas leak device | |

| Sliding boiler connection flange | |

| 7 pin power supply and first stage socket | |

| 7 pin second stage connection socket | |

| Complies with TS EN 676 A2 and 2016/426/EC GAR | |

| Electrical protection class | IP20 |

: Not Included / N/A

: Optional

: Included / Available

1K: Single Stage

2K: Two Stage

O: Modulating

M: Manuel

SM: Servomotor

İO: Ionization

F: Photocell

DA: Direct Ignition

PA: Pilot Ignition