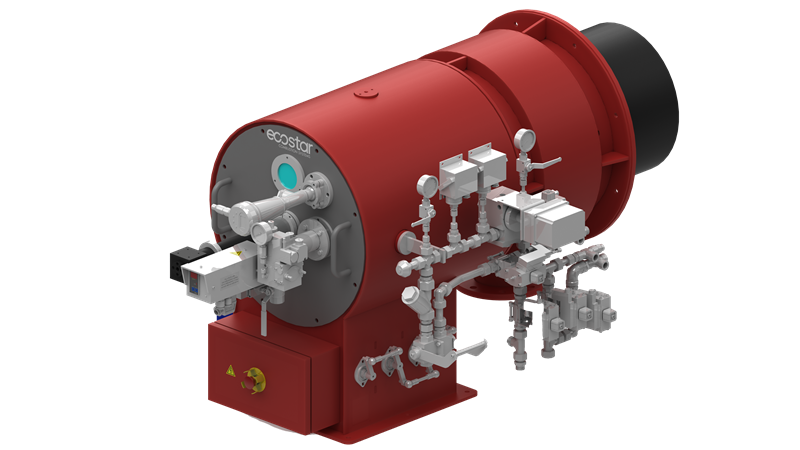

Industrial Burners

DIB

DIB 301

- ECOSTAR DIB series industrial burners with duoblock body structure are used in steam boilers, hot oil boilers, start-up applications and hot air generators.

- Natural gas, LPG, Heavy Oil, Light Oil, Biogas and special fuels can be used.

- With different combustion nozzle designs and flame pipe lengths suitable for the process, it can work in harmony in different combustion chambers, including modernized applications.

- Able to operate at combustion air fan suitable for the process and at 200°C combustion air temperatures. (It is painted with high temperature resistant paint; product capacity varies in hot air operation.)

- Suitable for manufacturing from completely stainless material in processes that require chemical resistance.

- Possible to request as mechanical, electronic and modulating depending on the process needs.

- Light oil filtering and pumping station is produced externally according to customer demand.

- Light oil filtering, heating and pumping station are produced externally according to customer demand.

- Special design pilot ignition burners are available for ignition (ECOSTAR PAL burner is standard in DIB-500 series and above).

- Combustion optimization with O2-CO trim system adaptation in electronic proportional burners, if demanded.

- Energy saving with fan speed control in electronic proportional burners, if demanded.

- Remote management by connecting to PLC systems using BMS (Burner Management System) or software.

- High fire safety thanks to flame control with photocell.

| Burner Type | Burner Capacity | Natural Gas Consumption | Diesel Consumption | Fuel Oil Consumption | |

|---|---|---|---|---|---|

| Max. MW | Max. kcal/h | Max. Nm³/h | Max. kg/h | Max. kg/h | |

| DIB-301 EL | 3,2 | 2.752.000 | 334 | 270 | 285 |

| * | ØD | L | H | F | C | K | S1 | S2 | S3 | ØM1 | ØM2 | ØM3 | VL | DN |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DIB 301 EL 1 | Ø259 | 1750 | 875 | 550 | 1100 | 725 | 300 | 350 | 385 | Ø380 | Ø430 | Ø500 | 320 | |

| DIB 301 EL 1 | - | 2000 | 875 | 550 | 700 | 325 | 325 | 300 | 350 | Ø380 | Ø430 | Ø500 | 570 | |

| DIB 301 MS 1 | Ø259 | 1750 | 875 | 550 | 1100 | 725 | 300 | 350 | 385 | Ø380 | Ø430 | Ø500 | 320 | |

| DIB 301 MS 1 | - | 2000 | 875 | 550 | 700 | 325 | 300 | 350 | 385 | Ø380 | Ø430 | Ø500 | 570 | |

| DIB 301 N 1 | Ø307 | 1750 | 875 | 550 | 700 | 325 | 300 | 350 | 385 | Ø380 | Ø430 | Ø500 | 320 | DN65 |

| DIB 301 N 1 | Ø268 | 2000 | 875 | 550 | 700 | 325 | 300 | 350 | 385 | Ø380 | Ø430 | Ø500 | 570 | DN65 |

| DIB 301 NEL 1 | Ø259 | 1750 | 875 | 550 | 1100 | 725 | 300 | 350 | 385 | Ø380 | Ø430 | Ø500 | 320 | DN65 |

| DIB 301 NEL 1 | - | 2000 | 875 | 550 | 700 | 325 | 300 | 350 | 385 | Ø380 | Ø430 | Ø500 | 570 | DN65 |

| DIB 301 NMS 1 | Ø259 | 1750 | 875 | 550 | 1100 | 725 | 300 | 350 | 385 | Ø380 | Ø430 | Ø500 | 320 | DN65 |

| DIB 301 NMS 1 | - | 2000 | 875 | 550 | 700 | 325 | 300 | 350 | 385 | Ø380 | Ø430 | Ø500 | 570 | DN65 |

*All dimensions in mm.

| SPECIFICATIONS | DIB 301 ME | DIB 301 EL |

|---|---|---|

| Electronic modulating control option | ||

| Mechanical modulating control option | ||

| Photocell flame control | ||

| Internal pilot ignition | ||

| ECOSTAR PAL pilot ignition burner | ||

| Pilot ignition gas valve | ||

| Air pressure switch | ||

| Options of operating with Gas / Heavy Oil / Light Oil / Gas-Light Oil / Gas-Heavy Oil | ||

| In liquid fuel products, high-pressure mechanic atomization lance or low-pressure air/steam-atomization lance | ||

| Ability to operate with hot combustion air* | ||

| Different mounting options | ||

| Serviceability without dismounting the burner from the boiler / service cover | ||

| Different flame tube length | ||

| Control via PLC with BMS or software | ||

| O2-CO combustion management system connection | ||

| Combustion air fan inverter connection | ||

| Fuel preparation stations (Gas line/Heavy Oil Station/Light Oil Station) | ||

| TSE EN Declaration of Conformity | ||

| CE Declaration of Conformity |

: Not Included / N/A

: Optional

: Included / Available

ME: Mechanical Modulating

EL: Electronic Modulating