Industrial Burners

Gazoram Burners

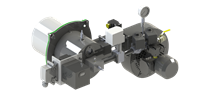

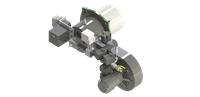

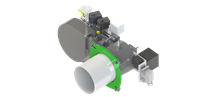

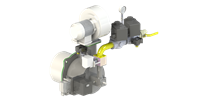

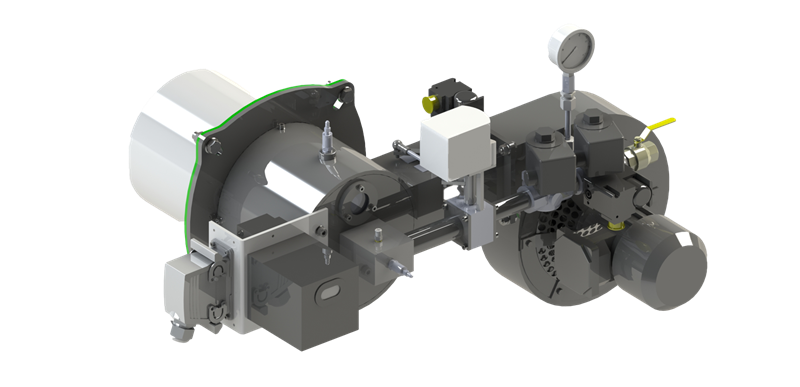

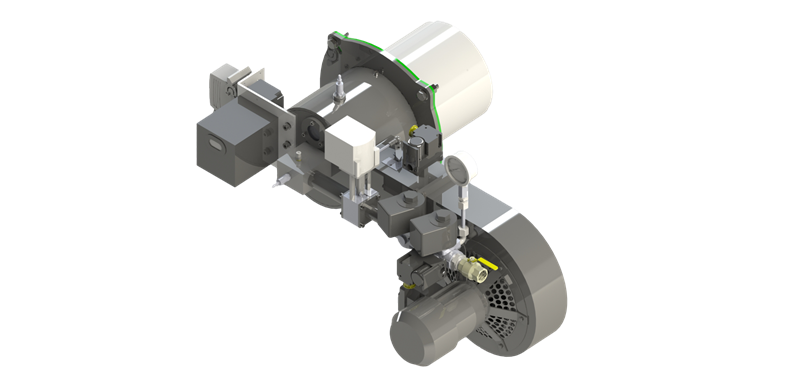

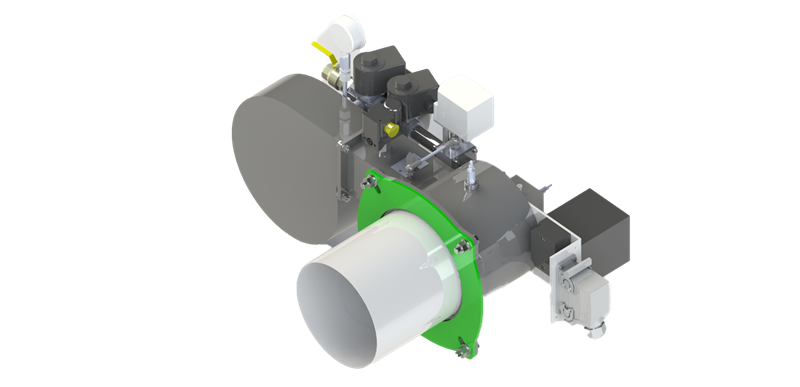

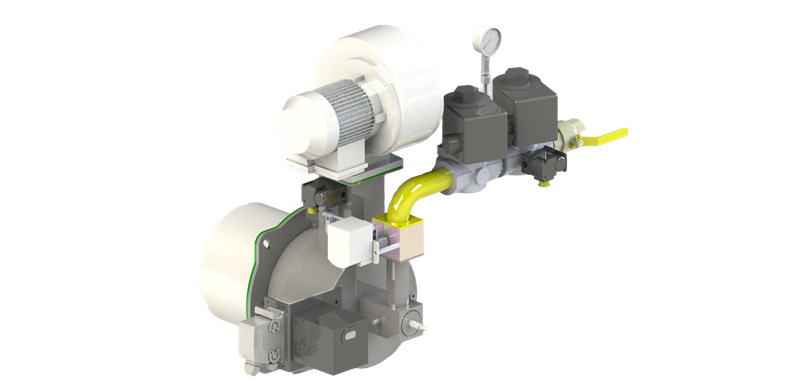

GRM 15

GAZORAM burners are nozzle-mixed burners and used in industrial direct-heating furnaces and drying applications. These furnaces usually have a balanced pressure in the combustion chamber and require burners with wide operating ranges. GAZORAM burners have a simple operating logic and easily adapt to many applications with different installation options. Gazoram burners operate at gas pressure of 21 to 50 mbar.

SPECIFICATIONS

- Operation in wide modulation range

- 7 different capacity options in the range of 5-1160 kW

- Operation with Natural gas and LPG

- Flame control with ionization or photocell (optional)

- Easy assembly and disassembly thanks to its design

- Easy operation and maintenance

AREAS OF USE

- Textile machinery

- Printing machines

- Drying and hardening furnaces

- Combustion furnaces

- Indirect air heating

- Textile drying

- Food processing/cooking

- Tempering

- Aluminum homogenization

- Conversion of ram-dryers working with hot oil and steam

STANDARD EQUIPMENT

- Electromagnetic safety and operating valve: An electromagnetic valve that ensures fully safe operation of the burner.

- Servo motor air/fuel adjustment: Precise air-fuel adjustment is provided by mechanically modulating klappes.

- Control Relay: Provides safe combustion control.

- Gas Pressure Switch: The gas pressure switch on the operating valve controls the gas pressure and prevents any problems that may occur due to pressure drops in the system.

- Air Pressure Switch: Ensures safety by checking for the availability of minimum combustion air required for safe combustion.

- Ionization: Provides flame control for safe combustion.

- Manometer: Ensures proper combustion settings and measuring of gas pressure.

- Spherical Gas Shut-Off Valve: Allows cutting off the gas for safety and maintenance purposes.

| BURNER TYPE | BURNER CAPACITY | BURNER CAPACITY | NATURAL GAS CONSUMPTION | 50 Hz VOLTAGE | ||||

|---|---|---|---|---|---|---|---|---|

| Min. kcal/h | Max. kcal/h | Min. kW | Max. kW | Min. Nm3/h | Max. Nm3/h | VAC | ||

| GRM 15 | 4.500 | 150.000 | 5,18 | 174,42 | 0,54 | 18,18 | 1N 230/3N 400 | |

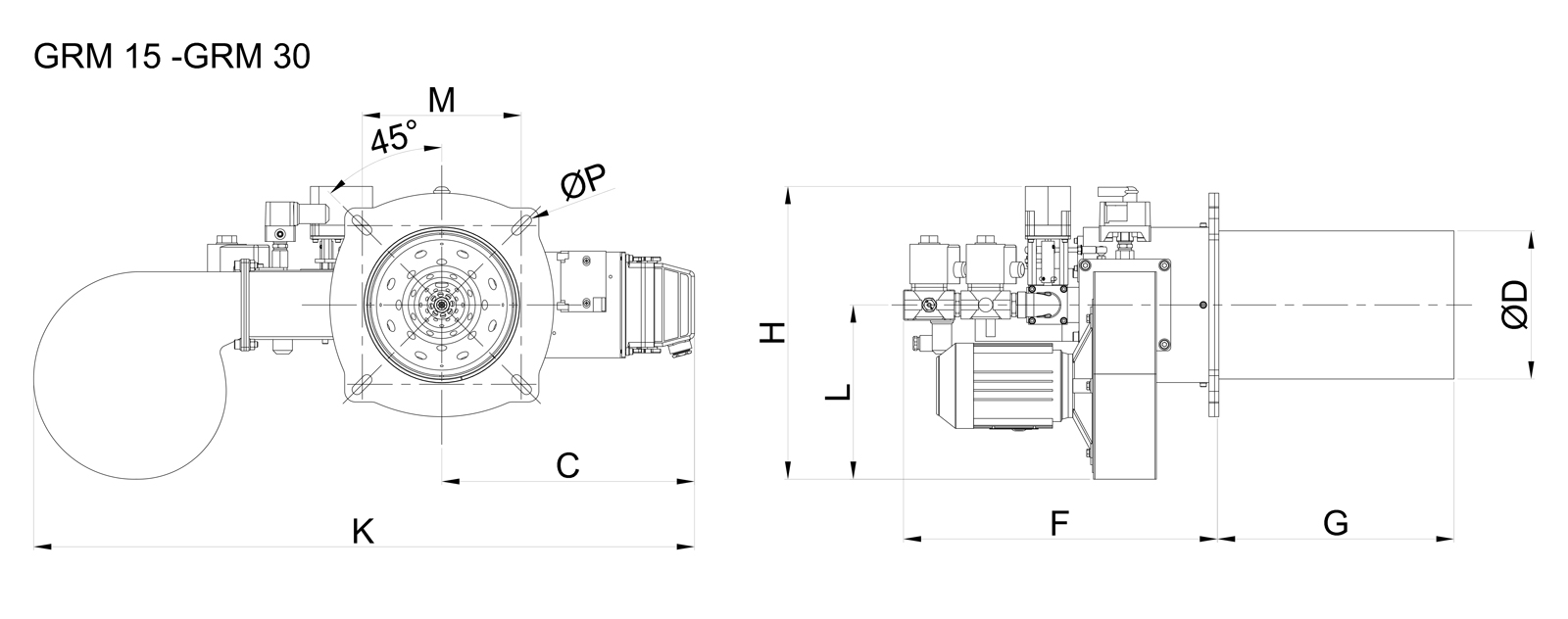

| * | ØD | G | H | L | F | C | K | M | ØP |

|---|---|---|---|---|---|---|---|---|---|

| GRM 15 | 158 | 200 | 420 | 260 | 450 | 350 | 900 | 185 | R7x34 |

*All dimensions in mm.